From Vision to Impact: How Monuments Turns University Innovations into Premium 3D-Printed Reality

- Monuments Marketing Team

- Sep 29, 2025

- 4 min read

Innovation becomes meaningful when it moves from paper to product, when a concept can be held, tested, and shared. At Monuments, we specialize in making that leap real.

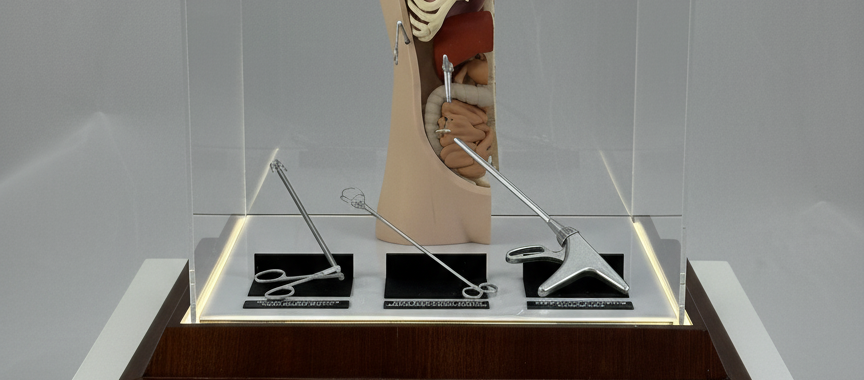

Recently, we partnered with King Faisal University (KFU) to convert 25 scientific innovations into high-quality 3D models, a fusion of engineering precision and visual elegance designed for demonstration, validation, and stakeholder engagement. We’re honored that six of these innovations were selected to represent the Kingdom at the Geneva International Exhibition of Inventions, a global stage for pioneering ideas. And as KFU ranks first globally among universities in patent registrations, we’re proud to have contributed to bringing this breakthrough pipeline to life, literally.

This project illustrates what defines Monuments: scientific rigor, premium craftsmanship, and an obsession with outcomes.

Why 3D Printing Is the Bridge Between Research and Real-World Adoption

University labs and R&D teams generate a steady stream of patents and proofs of concept. But to accelerate funding, partnerships, and commercialization, those ideas must be demonstrated clearly and convincingly. That’s where B2B 3D printing changes the game:

Rapid Proof & Iteration: Move from CAD to a physical prototype in days, not months.

Functional Testing: Validate ergonomics, tolerances, and assembly feasibility before committing to tooling.

Stakeholder Alignment: High-fidelity models communicate value to investors, industry partners, and exhibitors instantly.

Cost Efficiency: Reduce rework and de-risk capital investment with early physical validation.

Inside the KFU Collaboration: 25 Innovations, One Cohesive Fabrication Strategy

Turning 25 distinct scientific concepts into exhibition-grade models demanded a disciplined, scalable process. Our approach combined engineering excellence with design storytelling:

1) Discovery & Design for Additive Manufacturing

We reviewed each project’s scientific concept, constraints. Our engineers applied Additive Manufacturing principles to optimize geometries, reduce mass, consolidate parts, and prepare for realistic assembly or motion where required.

2) Material & Process Selection

We matched each innovation with the right technology and material properties: strength, stability, transparency, surface finish, and biocompatibility (where relevant). Typical selections included:

SLA (Engineering Resins): High-resolution, smooth surfaces for enclosures, micro-features, and display models.

Acrylic (PMMA): Transparent display models with smooth surface finish and excellent optical clarity—ideal for cosmetic parts, faceplates, and exhibition-ready samples.

FDM (ABS/PC/CF-Nylon): Cost-effective, robust parts for fixtures, jigs, and early fit checks.

Finishes: Vapor smoothing, bead blasting, painting, metalization, and branding overlays for exhibition-ready presentation.

3) Tolerance & Assembly Engineering

For multi-component systems, we engineered press-fits, snap-fits, and captured fasteners to enable realistic interaction during demos while ensuring reusability across events.

4) Visual Storytelling

Exhibition success is more than accuracy—it’s clarity. We crafted color-coded components, cutaway views, exploded assemblies, and annotation plaques so each model communicates its scientific value at a glance.

5) QA & Pre-Exhibition Stress Tests

Every deliverable underwent mechanical fit checks, surface inspection, and packaging validation. Transport-safe cases ensured that what left our facility arrived Geneva-ready.

Results: Six Innovations on a Global Stage

From calibration rigs to biomedical concepts and engineered mechanisms, the final models captured both function and form. The selection of six innovations for the Geneva International Exhibition of Inventions validated the work’s impact: precise engineering, premium presentation, and a unified narrative that represents the Kingdom’s innovation leadership.

What Sets Monuments Apart for B2B 3D Printing in Saudi Arabia

Enterprise-Grade Reliability: Consistent lead times, traceable materials, and documented QA.

Multi-Technology Fleet: SLA, FDM, and post-processing labs under one roof for end-to-end control.

Engineering Partnership: We’re not just a print shop—we’re a technical extension of your R&D or product team.

Showroom-Quality Finishing: Exhibition models that persuade: from subtle textures to automotive-grade paint.

Scalable to Production: Bridge manufacturing and low-volume runs with repeatable quality and supply planning.

Where We Add the Most Value

Universities & Research Centers: Patent demos, human-factors mockups, teaching aids.

Industrial & Energy: Housings, brackets, tooling, jigs, fixtures, flow visualization models.

Healthcare & MedTech: device enclosures, anatomical models.

Aerospace & Automotive: Ventilation ducts, lattice structures, topology-optimized brackets, wind-tunnel models.

Event management & exhibitions: custom giveaway, scaled models, demo-ready mockups for live activations, branded display stands and plaques.

Real estate & development: modeling residential plans for developers (facades, sections, floor levels), neighborhood/site scaled models, and interior fit-out inserts.

Our Engagement Model (Clear, Fast, Accountable)

Brief & NDA → Share your goals, constraints, timelines.

Design Review → Additive Manufacturing recommendations and risk flags.

Quote & Schedule → Transparent pricing and committed delivery dates.

Prototype & Iterate → Rounds of feedback to lock form and function.

Finish & Package → Exhibition-ready quality with documentation.

Optional Bridge Production → Scale to pilot batches or supply spares.

Practical Tips for Successful 3D Printing Projects

Start with Intent: Is the model for testing, showcasing, or manufacturing sign-off? The answer shapes material and process choices.

Share Assembly Context: Interfaces, and mating parts help us engineer the right tolerances.

Plan Finishes Early: Paint, texture, and branding layers affect timelines and unit cost.

Design for Serviceability: For demo units, modularity and access panels reduce risk during events.

A Milestone for Saudi Innovation—And a Blueprint for What’s Next

As KFU celebrates global recognition in patent registrations, it’s clear that the Kingdom’s innovation engine is accelerating. Our collaboration showcases a repeatable blueprint for turning intellectual property into tangible impact—ready for testing, exhibitions, and industry partnerships.

At Monuments, we’re committed to bridging science, design, and storytelling through premium 3D fabrication. If you’re ready to bring your vision to life—faster and with greater confidence—we’re ready to help.

Comments